Helical piles have a long history of use in the United States. Helical screw piles were first installed in the 19th century as foundations for lighthouses. Maplin Sands Lighthouse was constructed between 1838 and 1840 in the U.K. and was the first known use of helical screw piles. The first U.S. constructed helical pile lighthouse was at Brandywine Shoal, constructed in 1848. The piles were installed using 4 foot capstan bars turned by 30 men.

Helical piles have made significant advances since. Structural and mechanical engineering has improved the system components and geotechnical engineering has improved our understanding of the interactions between soil and deep foundations. Equipment advances have also allowed for significant improvements in construction methods.

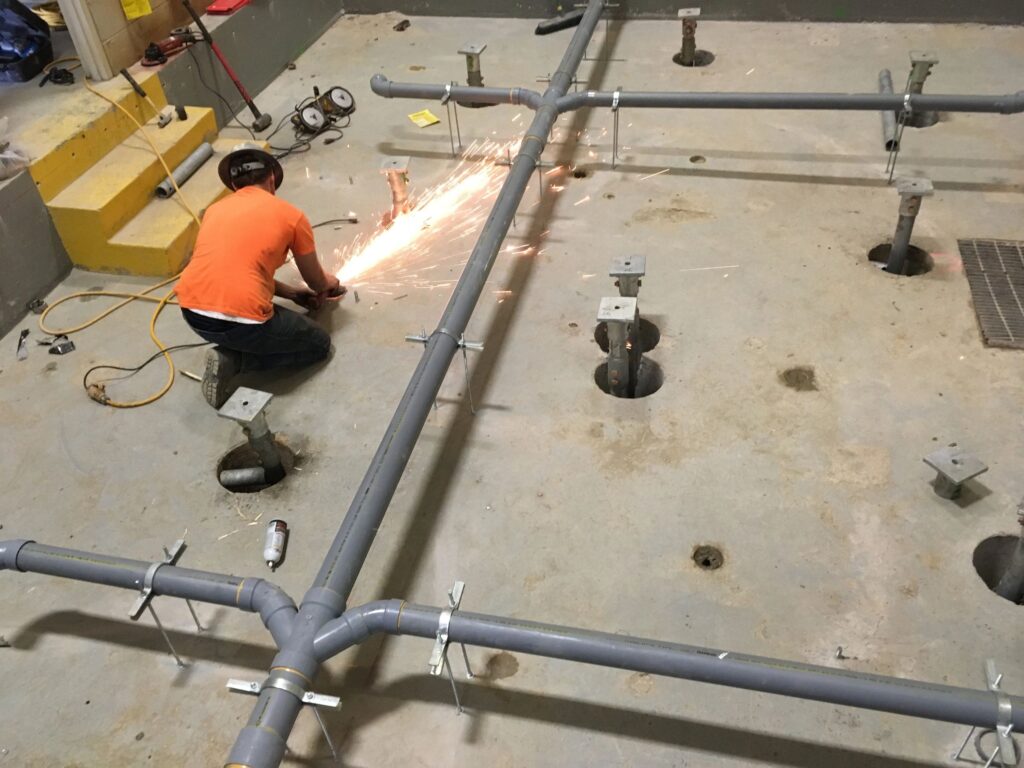

Helical piles can be designed for a wide range of structural loads and can be installed quickly and efficiently in many different types of soils. Not all structural and soil conditions are suitable for helical piles, so partnering with experienced designers and installers is critical for the success of your project.

During installation of a helical pile system, quality control/assurance for each pile is critical. In the early days of the industry, estimating the capacity of the pile was difficult. The piles are installed using hydraulic gear motors that require a correlation between gear motor torque and pile capacity. Seat of the pant approaches such as installing a pile until the gear motor stalled out or counting the number of “twists” in a bar were used. Calibration charts supplied by the gear motor manufacturers to convert between hydraulic pressure and torque can be used but require re-calibration as the gear motor ages.

Current best practice in the industry is to use a direct read torque monitor during installation. These torque monitors directly measure torque using strain gauges and are positioned between the gear motor and helical shaft allowing for continuous measurement of applied torque. The correlation between torque and pile capacity has been determined by analyzing thousands of load tests performed by installers, engineers, and manufacturers all over the world.

Foundation Specialties has been a certified installer of helical piles since 1991. Using best industry practices has allowed us to successfully install thousands of helical piles for new and retrofit foundations.

Ready to Get Started?

FSGC is committed to safety, service, and excellence. We look forward to partnering with you to design and build the best solutions for your project.